How To Choose The Correct Submersible Pump

The size, shape, and capabilities of a submersible pump can vary greatly from application to application. In this article I will discuss the differences between our many different styles of submersible pumps and help you decide which pump to choose for your application.

Although we have quite a large selection, our submersible pumps can be broken down into four main categories: High Head Effluent, Sump/Effluent, Sewage Ejector, and Sewage Grinder.

High Head Effluent pumps are primarily used behind an aerobic system and pump to either a spray irrigation system or drip irrigation system. The Sump/Effluent submersible pumps are designed to pump relatively clean water usually behind an aerobic system or septic tank. The Sewage Ejector and Sewage Grinder pumps are both used to pump raw sewage. I will explain each one of these categories in much more detail below.

3 THINGS YOU MUST KNOW IN ORDER TO CHOOSE THE CORRECT PUMP

To make a decision on which type of pump will work best for any certain application there are four questions you will need to know the answer to:

What is the application? (What is pump’s job? What kind of materials will the pump be asked to relocate? Raw Sewage or Clear Water)

What kind of head pressure will the pump be pushing against? (The numbers you need to know is how high vertically the pump need to push the water and the length of the horizontal run.)

What kind of flow rates will the pump need to handle? (Roughly how many GPM do you expect to run through the pump at MAX capacity)?

If you can answer these three questions, then choosing a submersible pump will be a piece of cake!

HEAD PRESSURE EXPLAINED

Head Pressure is simply the force that the pump must overcome to be able to push the water to its destination. This number is figured by calculating the vertical lift (static head) along with pipe friction loss using the size of pipe, length of run, and flow rate of the pump. These two figures put together are what we call Total Dynamic Head (TDH). If you do not know the TDH for your application, our technicians will be able to calculate it for you simply knowing the vertical lift and the run distance.

The pumps are listed on our website as having a shut off at a certain feet of head, the Total Dynamic Head that your pump must overcome has be lower than that shut off number in order for the pump to work correctly. Generally if the numbers are relatively close, going to the next size larger unit is highly recommended.

HIGH HEAD EFFLUENT SUBMERSIBLE PUMPS

HIGH HEAD EFFLUENT SUBMERSIBLE PUMPS

High Head Effluent submersible pumps, also known as turbine pumps or deep water well pumps, are high pressure submersible pumps. They are primarily used in the septic system industry for spray irrigation or drip irrigation systems. These pumps are only designed to handle clear water or treated wastewater, so they are normally only installed behind an Aerobic Treatment System.

The High Head Effluent pumps that are used across the Aerobic Septic System industry are all fairly standard. Most you will see will be rated from 10 to 20 Gallons per minute and dimensionally will be very similar. At Septic Solutions we offer two different pumps in this category.

FRANKLIN ELECTRIC LITTLE GIANT

The Franklin Electric Little Giant High Head Effluent pump is a mid-suction unit. This means the pump will intake water at the center of the unit. Generally this is the best design in an aerobic system, because it allows any solid material that makes it to the pump tank to settle on the bottom of the tank and prevents the intake screen of the pump from clogging up with debris causing eventually the pump to fail prematurely. The Franklin Electric Little Giant is available in both 10 GPM and 20 GPM models, however the 20 GPM model is by far the most commonly used.

STA-RITE DOMINATOR

The Sta-Rite Dominator High Head Effluent pump is a bottom suction unit. This means the pump will intake water at the bottom of the unit. Although this is a more risky set up in an aerobic system design, some systems use the bottom suction units and elevate them off of the bottom of the tank using a PVC pipe spacer. If this is the kind of set up you are replacing, the Sta-Rite Dominator is going to be your best choice. We only carry this model in the 20 GPM series.

SUMP/EFFLUENT SUBMERSIBLE PUMPS

SUMP/EFFLUENT SUBMERSIBLE PUMPS

Our Sump and Effluent pumps are designed to handle wastewater with minimal solids or clear water. Most of our Effluent pumps have a 1-1/2’’ NPT discharge and some of the large units even have a 2’’ discharge. These pumps can handle smaller solids up to 3/4’’ in size. These units are normally used to pump discharge from a septic tank or an aerobic system to a drain field, secondary treatment system, or surface discharging point.

We carry many brands of Sump/Effluent Pumps which include Little Giant, Liberty, Myers, and Ashland. All manufacturers that we carry provide very high quality, low maintenance units. Our effluent pumps range from 1/3 HP all the way up to 2 HP, and which unit you decide to use will vary depending on how you answer questions 2 and 3 laid out above. The larger the horse power rating of a unit the higher the head pressure and volumes of water it can handle.

SEWAGE EJECTOR PUMPS

SEWAGE EJECTOR PUMPS

Sewage Ejector submersible pumps can handle raw sewage pumping jobs. These pumps are designed to pump raw sewage wastewater, usually from a pump station in a basement or just outside of the house, to your septic tank or aerobic treatment system. Our Sewage Ejector pumps can handle up to 2’’ solids and have either a 2’’ or 3’’ NPT discharge. Sewage Ejector pumps are great for any low pressure pumping jobs.

We carry sewage ejector pumps from Little Giant, Liberty, Myers, and Ashland. They range from 4/10 HP all the way up to 2 HP. Again, which unit you ultimately need to use depends completely on the answers to Questions 2 and 3 stated in the introduction section above.

SEWAGE GRINDER PUMPS

Sewage Grinder pumps are also designed to handle raw sewage pumping jobs, just like the Sewage Ejector pumps. However, Sewage Grinder pumps are much more powerful. These pumps can grind up sewage into a slurry and pump it at a very high pressure to its destination. There a couple of applications that these pumps are normally used in. The first is to pump from a residence into a shared sewer main. The second is to pump over extremely long distances, or up over very high elevation changes.

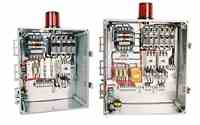

All of our Grinder Pumps are 2 HP units and have 1-1/4’’ NPT discharges. They are also available in Little Giant, Liberty, Myers, and Ashland brands. Each model comes in two forms, one with internal capacitors and one without internal capacitors. The most commonly used forms are with internal capacitors. These require no control panel for operation. The units without internal capacitors require a special control panel with built in capacitors to operate the pump.

All of our Grinder Pumps are 2 HP units and have 1-1/4’’ NPT discharges. They are also available in Little Giant, Liberty, Myers, and Ashland brands. Each model comes in two forms, one with internal capacitors and one without internal capacitors. The most commonly used forms are with internal capacitors. These require no control panel for operation. The units without internal capacitors require a special control panel with built in capacitors to operate the pump.

Important Warning: 2.0 HP grinder pumps must be used in scenarios where there will be at least a minimum of 30 feet of head pressure put on them. If they do not have to pump against at least this much back pressure, the motor will begin to spin at an extremely high rate of RPMs causing it to burn up fairly quickly. Therefore, if you are not pumping into a shared sewer main or have less than 30 feet of head, you do want a Sewage Ejector pump not a Sewage Grinder pump.

With this information, you are now ready to take on the task of purchasing a new submersible pump. We have the ability to get different versions of the pumps as they are listed on the website. If you cannot find a pump on our site to fit your application, feel free to call us and we can determine if we have something that will work for you.