Why Is My Septic Alarm Going Off?

If you are getting an alarm from your septic system, obviously something is wrong. In this Knowledge Base article we will go through the most common causes of a septic alarm and how to check for them.

If you are not familiar with the workings of your system, or do not feel comfortable checking the system on your own, we would suggest calling your local service provider to figure out the issue.

If you are not familiar with the workings of your system, or do not feel comfortable checking the system on your own, we would suggest calling your local service provider to figure out the issue.

ALARMS ON CONVENTIONAL SEPTIC SYSTEMS

A conventional septic tank does not have any type of aeration device. If you are getting an alarm on this type of system, generally the alarm indicates high water level. The main causes of high water level in a conventional septic tank system are:

- The effluent filter inside the septic tank is clogged. Many conventional septic tank systems have an effluent filter on the discharge of the tank. This filter should be cleaned approximately every 6 months. If the filter becomes clogged with solids, it will slow the flow of water leaving the system causing the water level in the septic tank to raise.

- The submersible pump has failed or the float that controls the submersible pump has failed. Not all conventional septic tank systems will require a submersible pump but some may have one. A submersible pump is used in instances when the septic tank cannot gravity feed to the secondary treatment system. The failure of a submersible pump or float switch will cause a high water level in the pump tank and the septic tank.

- The outlet line is plugged or the leach field has failed. If the septic tank does not have a submersible pump, the other cause of high water level would be a plugged outlet line or a failed leach field.

A common misconception is that a high level alarm on a septic tank indicates that the tank needs pumped out. A high level alarm will not indicate when a tank needs pumping, and while pumping the tank out may resolve the alarm in the short term, once the tank fills back up the alarm is likely to re-occur because the main problem with the system has not been resolved.

ALARMS ON AEROBIC TREATMENT SYSTEMS

ALARMS ON AEROBIC TREATMENT SYSTEMS

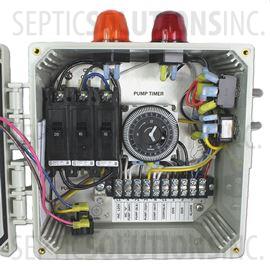

Aerobic Treatment Systems usually consist of an aeration device that can be an external air pump or air compressor, or an internal unit such as a shaft aerator or a submersible aerator. The cause of an alarm on aerobic systems is either the failure of the aeration device or high water level inside the tank. If your alarm or control panel does not indicate which alarm is active, below are some steps to help identify the problem.

- Check to see if the aeration device is running. If you have an air pump or compressor that sits above ground, check the unit to ensure that it is running. You can also disconnect the main hose going to the aerobic tank and feel if the unit is putting out air. If you have an in tank aerator, take off the lid of the aeration chamber and see if the aerator is running. If the aerator is not operating or not putting out air, this is the cause of your alarm. The aerator will need to be repaired or replaced depending on the type and condition of the unit. If the aerator seems to be operating normally, then the most likely cause of the alarm is high water level. This is not an overnight emergency, however we suggest getting the system up and running within 1-2 weeks of failure.

- Check to see if the water level is high in the aeration tank and/or pump tank. The water level should be below the inlet and at the bottom of the outlet of a properly working system. If the water level is high, below are the likely causes.

- In a gravity discharging system, the cause of high water level would be a blockage in the outlet line. The most common culprit is the chlorine feeder. Pull the out the tube where you put chlorine tablets and clean any debris from the feeder. Also if the system surface discharges, be sure the discharge outlet is clear from weeds and debris.

- In a system with a submersible pump, the cause of high water level is either that the submersible pump has failed or the float switch that turns the pump on and off has failed. The best way to test a float switch is using an ohm meter to test continuity. The switch should test out closed in the raised position and open in the down position. The submersible pump can be tested by disconnecting the pump from the float switch and powering it directly from a known working power supply. Please note that when doing this, the pump will not automatically shut off by itself and you will need to disconnect it from power to turn it off before the tank is pumped dry.

THIS DID NOT RESOLVE MY ISSUES

If none of the troubleshooting mentioned above seems to answer the problem you are having, there could be issues in your control panel or alarm that are either causing the system to malfunction or are giving you a high level alarm. In this instance we would recommend calling a professional service provider to check out the system and resolve the problem.